Rapid Prototyping

Services UK

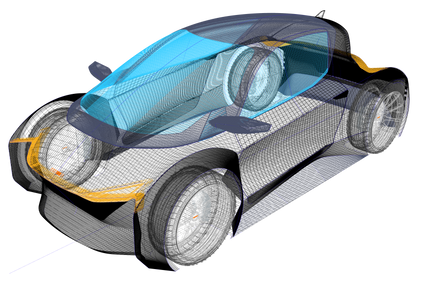

Transform your concepts into functional prototypes in 3-10 days. Test, iterate, and validate designs quickly before committing to expensive production tooling.

Validate Ideas Faster, Reduce Risk

Rapid prototyping enables you to test concepts, gather feedback, and refine designs before investing in expensive production tooling or large manufacturing runs.

Functional Prototypes

Functional Prototypes  Engineering Validation

Engineering Validation  Concept Models

Concept Models Fast Iteration Cycles

Test and refine designs quickly with rapid turnaround

Cost-Effective Testing

Validate concepts before committing to production tooling

Functional Prototypes

Production-grade materials for real-world testing

Design Validation

Identify issues early in the development cycle

Rapid Prototyping Capabilities

Professional-grade equipment and materials for precision prototyping across demanding applications.

Materials & Technologies

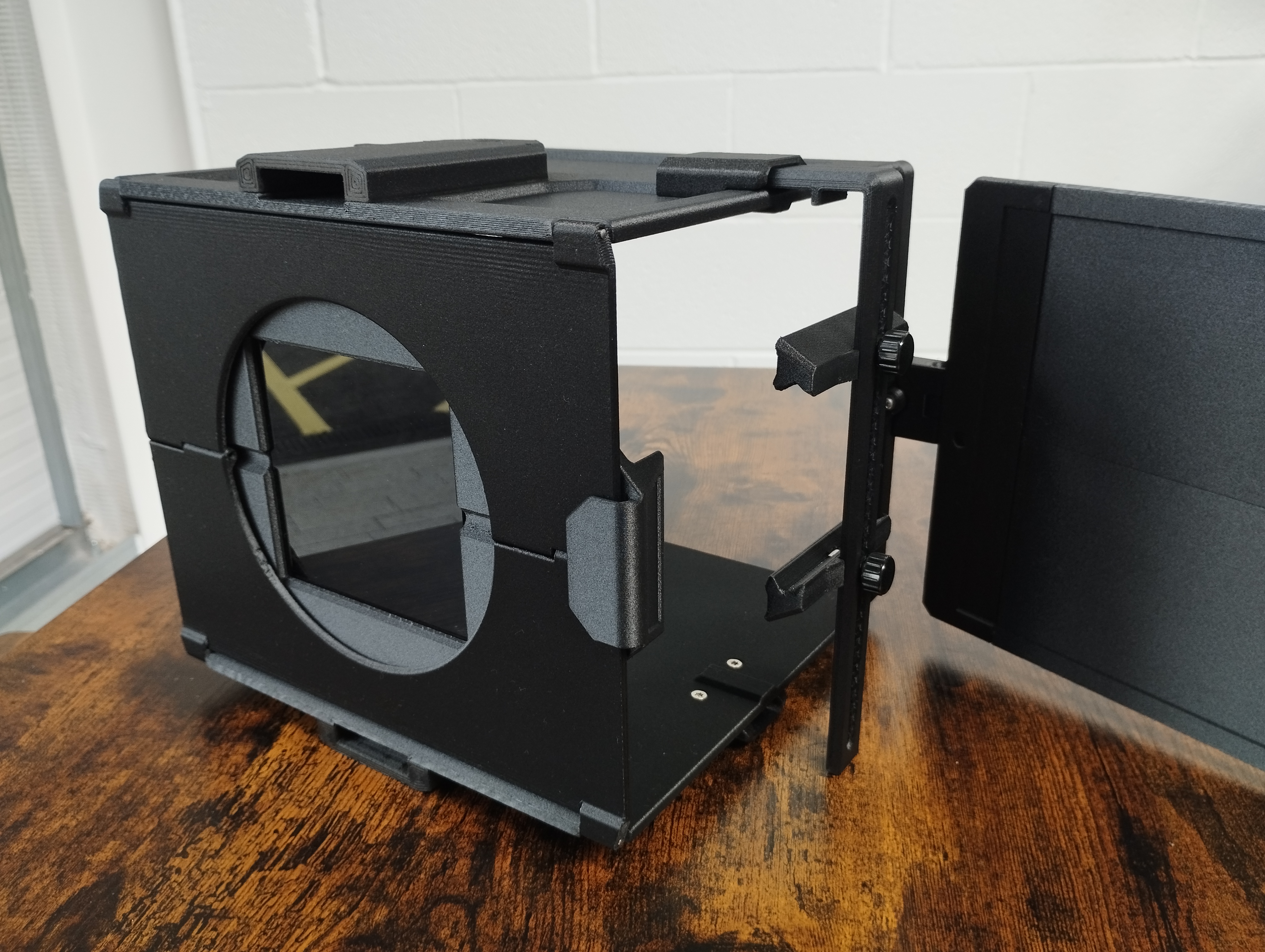

Our rapid prototyping services utilise industrial-grade 3D printing technologies including FDM, SLA, and SLS processes. We work with over 25 engineering-grade materials ranging from standard PLA and ABS through to high-performance options like PEEK, carbon fibre composites, and glass-filled nylons.

For functional prototypes requiring specific mechanical properties, we offer materials with high temperature resistance (up to 300°C), chemical resistance for automotive and industrial applications, and UV-stable options for outdoor use. Each material is selected to match your prototype's intended testing environment.

Precision & Tolerances

Standard tolerances of ±0.1mm for most applications, with tighter tolerances available for precision engineering requirements. Layer heights from 0.05mm for fine detail work up to 0.3mm for rapid concept models. Maximum build volumes accommodate parts up to 300 x 300 x 400mm in a single print.

Post-processing options include vapour smoothing, CNC machining of critical surfaces, painting, and assembly of multi-component prototypes. We can match specific Pantone colours and surface finishes to replicate production intent.

Quality Assurance

Every prototype undergoes dimensional verification before dispatch. For engineering prototypes, we provide inspection reports documenting critical dimensions and material certificates. Our quality process ensures your prototype accurately represents your CAD design, reducing iteration cycles and accelerating your development timeline.

Build Volume

300 x 300 x 400mm

Single piece maximum

Layer Resolution

0.05 - 0.3mm

Application dependent

Tolerances

±0.1mm

Standard accuracy

Materials

25+

Engineering grades

From Concept to Production Validation

Choose the right prototype type for your development stage and testing requirements.

Concept Models

Visual representations for design reviews and stakeholder presentations

Ideal For:

- Design reviews

- Market research

- Investor presentations

- Team collaboration

Functional Prototypes

Working models for testing fit, form, and function in real-world conditions

Ideal For:

- Mechanical testing

- Assembly validation

- User testing

- Performance evaluation

Engineering Prototypes

Production-grade materials and tolerances for comprehensive validation

Ideal For:

- Stress testing

- Environmental testing

- Certification samples

- Pre-production validation

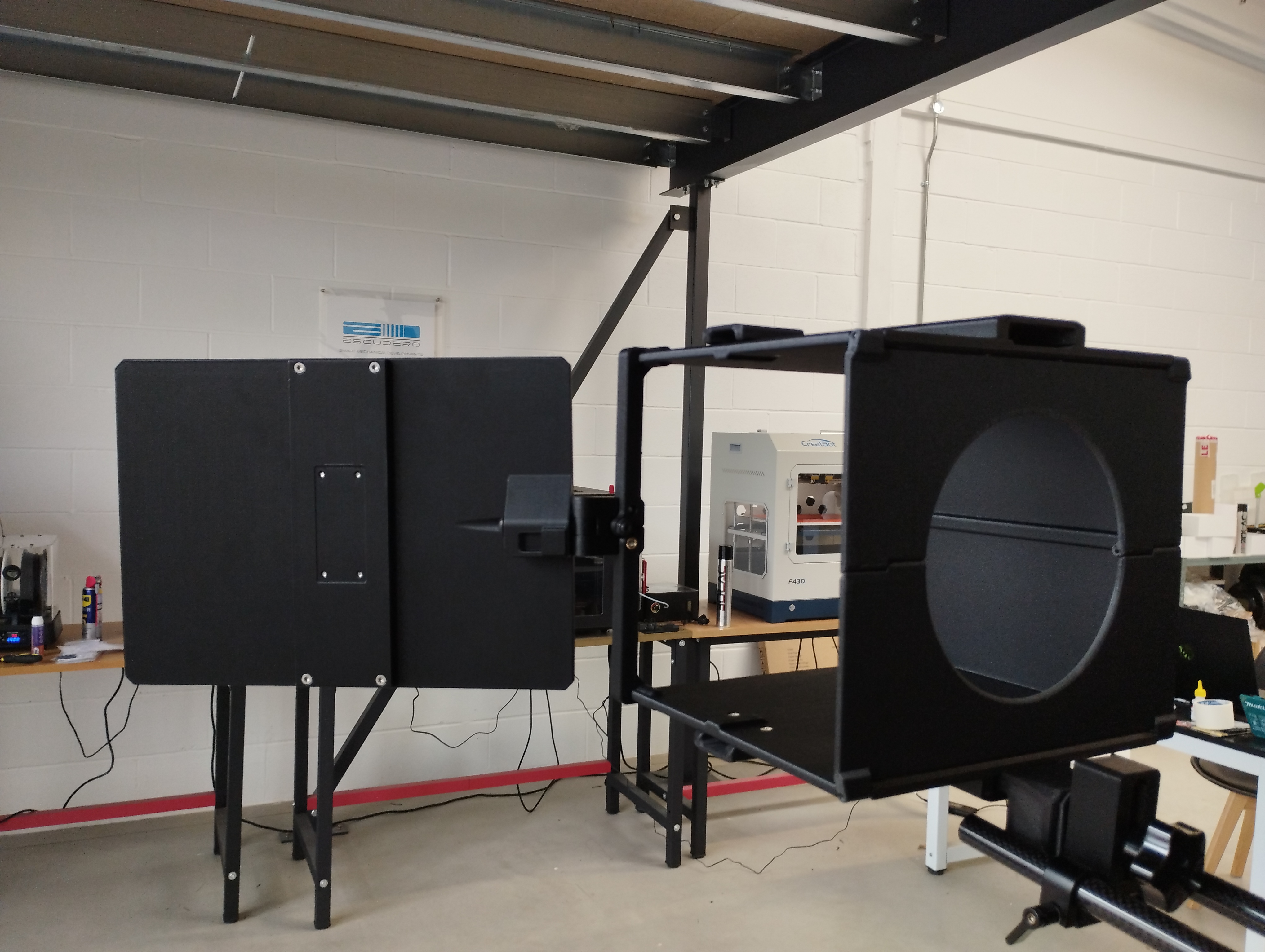

Streamlined Workflow for Speed

Our proven process ensures fast turnaround without compromising on quality or precision.

Submit Design

Upload CAD files or sketches. We'll review for manufacturability and suggest improvements.

Rapid Quote

Receive detailed quote with material recommendations and timeline within 24 hours.

Print & Test

Parts manufactured with quality checks. We can provide photos during production.

Iterate & Refine

Review prototype, make design changes, and quickly produce revised versions.

Trusted Across Multiple Sectors

Real Results from Rapid Prototyping

See how our rapid prototyping services helped clients accelerate development and reduce costs.

Classic Car Dashboard Prototype

Challenge

Needed custom gauge housing for vintage restoration within 2 weeks

Solution

Created functional prototype in ABS for test fitting, then final version in carbon fiber composite

Perfect fit achieved in one iteration, saved 6 weeks vs traditional manufacturing

Industrial Valve Component

Challenge

Required pressure-tested prototype for new valve design certification

Solution

Produced engineering prototype in Nylon with precise threading and sealing surfaces

Passed all pressure tests, validated design before tooling investment of £15,000

Ready to Accelerate Your Product Development?

Upload your design files today and receive a detailed quote within 24 hours. Our team will work with you to select the right materials and prototyping approach for your needs.